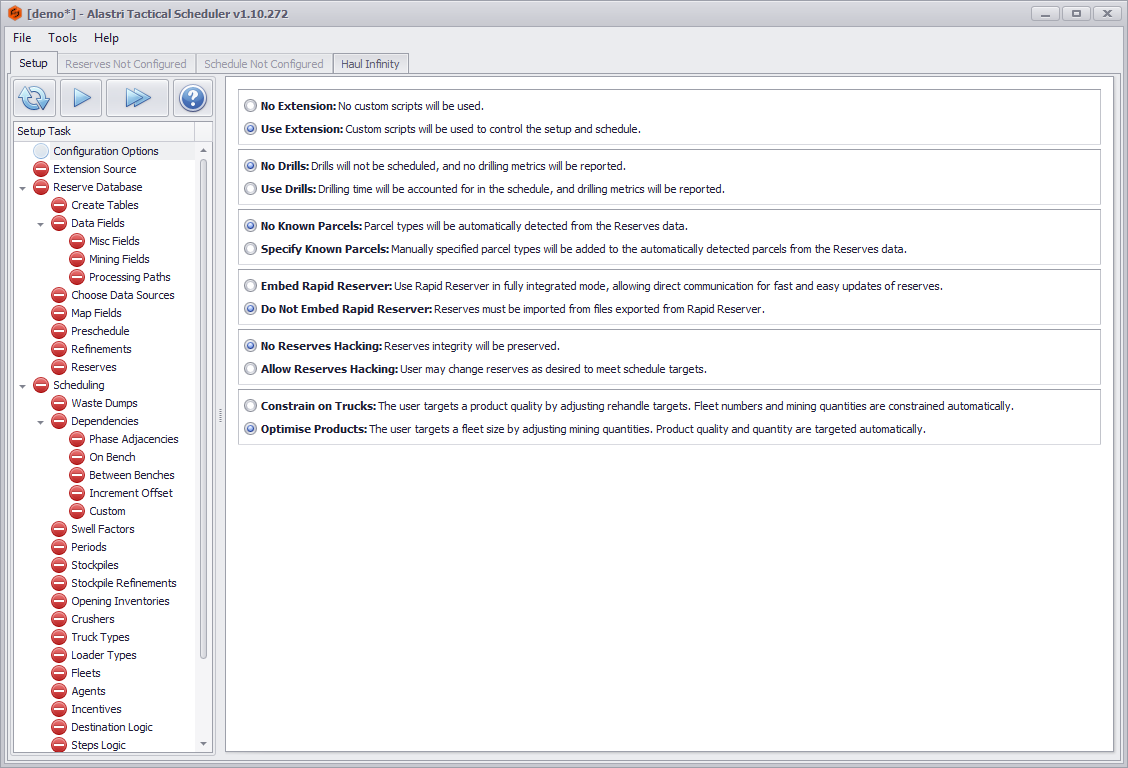

ATS Configuration Options

Choose the setup steps and schedule mode to use in the project.

Use Extension

Check this option to allow scripted changes to the reserves database, stockpile inventories, equipment performance, processing plant performance, and reporting fields.

Contact your Alastri support representative for assistance with Site Specific Extensions.

Use Drills

Turning on drills adds new equipment types and reserves fields to the project. Drill scheduling accounts for delays relating to blasted stocks, available real estate, and fleet logistics.

See also: ATS Drill Scheduling.

Specify Known Parcels

By default, the project will only list material types that are imported with the reserves. The user may wish to specify some additional known parcels such as topsoil, or legacy stockpile inventory.

Embed Rapid Reserver

By default, scheduling inventories are exported from Rapid Reserver and imported into Tactical Scheduler.

Embedding Rapid Reserver allows short term planners to edit the blast master during scheduling, without having to re-import the reserves. .

Allow Reserves Hacking

In the case that the imported reserves are known to be incorrect or out of date, the user may choose to allow reserves hacking and directly edit the quantities and qualities of material in a block.

Constrain on Trucks / Optimised Products

These are the two modes of scheduling available to Tactical Scheduler users.

Truck Constrained

Equipment stops when it runs out of hours. Stockpiles must be reclaimed manually, and there is no automatic grade targeting..

Recommended for users who need exactly 100% utilisation or manual stockpile control.

Optimise products

Equipment stops when it hits plan targets. There is no limit on equipment hours, it will overflow to reach target.

Recommended for users who need exact product blending and automatic stockpile management.