ATS Step Reports

Step Reports display every schedule transaction with the details for the selected headers.

Listed in this section are a number of example step reports for error-checking your project setup.

Call Factor Checks

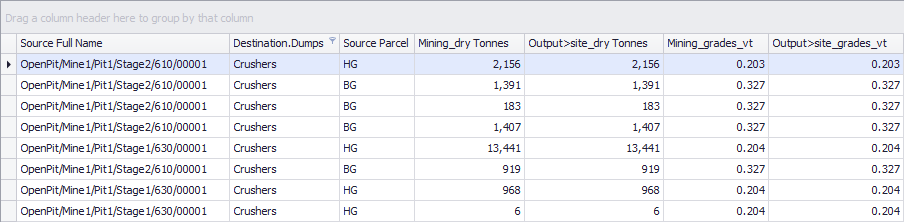

Create a step report to spot check the plant recovery and call factors.

- Go to Schedule tab > Reporting tab > Add Step Report.

- Click in the name field and rename to "Product Check".

- From the right hand field list, drag in:

- Source Full Name

- Destination.Dumps (filter to 'Crushers')

- Source Parcel

- Mining_dryTonnes

- Output>plant_ship_SubProducts_lump_dryTonnes (or equivalent)

- Output>plant_ship_SubProducts_fines_dryTonnes (or equivalent)

- Mining_grades_fe

- Output>plant_ship_SubProducts_lump_grades_fe (or equivalent)

- Output>plant_ship_SubProducts_fines_grades_fe (or equivalent)

Use this table to confirm that subproduct ratios, process recovery, call factors and moisture changes are being correctly applied to crusher feed from both reserves and stockpiles.

For added clarity, consider adding 'Recovery' as a product field so that it can be reported as a line item.

Haulage Spot Check

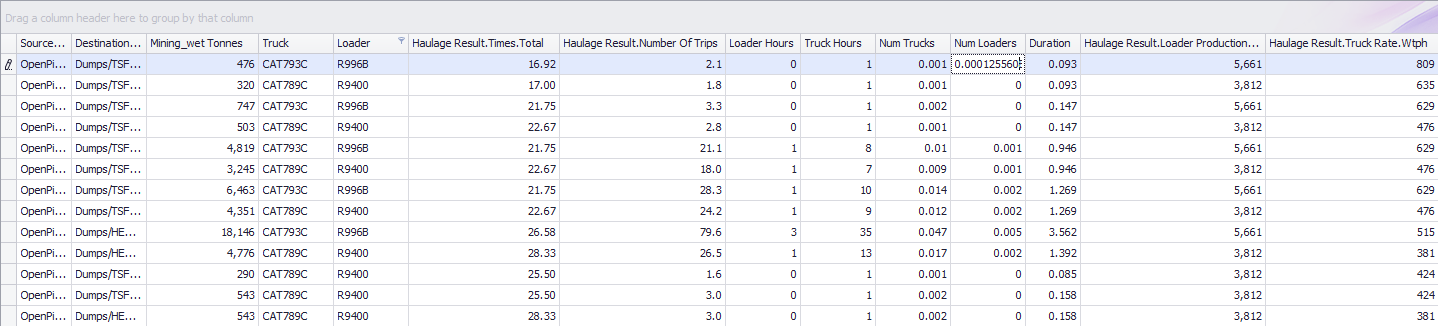

Create a step report to review the Haul Infinity results.

- Go to Schedule tab > Reporting tab > Add Step Report.

- Click in the name field and rename to "Haulage Check".

- From the right hand field list, drag in:

- Source Full Name

- Destination Full Name

- Mining_wetTonnes

- Truck

- Loader

- HaulageResult.Times.Total

- HaulageResult.NumberOfTrips

- LoaderHours

- TruckHours

- NumLoaders

- NumTrucks

- HaulageResult.LoadProductionRate.Wtph

- HaulageResult.TruckRate.Wtph

Use this table to spot check the truck and loader time usage per haul.

Step report showing the haulage information for each transaction in the schedule

| Field | Source |

|---|---|

| HaulageResult.LoaderProductionRate.Wtph | Calculated from productivity inputs. |

| HaulageResult.TruckPayload | Calculated from Haul Infinity > Setup > Parameters. |

| HaulageResult.Times.Total (mins) | Calculated return cycle time for a single complete haul. |

| HaulageResult.TruckRate.Wtph | HaulageResult.TruckPayload / HaulageResult.Times.Total * 60 |

| TruckHours | mining_wetTonnes / HaulageResult.TruckRate.Wtph |

| LoaderHours | mining_wetTonnes / HaulageResult.LoaderProductionRate.Wtph |

| HaulageResult.NumberOfTrips | TruckHours / HaulageResult.Times.Total *60 |

| NumTrucks | TruckHours / (Calendar Direct Hours per Unit) |

| NumLoaders | LoaderHours / (Calendar Direct Hours per Unit) |

| Duration | LoaderHours / (Loader Time Usage %) |

Note that the HaulageResult fields return the instantaneous property of the haul cycle. For instance, "HaulageResult.FuelBurn.Total" is the fuel burn of a single return trip on that haul, not the actual fuel burned for this schedule transaction (which may represent a fraction of a haul). The same goes for HaulageResult.Distance, HaulageResult.Times, and so on.

To calculate the actual time or fuel used, you must take the sumproduct of the property with HaulageResult.NumberOfTrips.